- افریقايي

- البانیایی

- امهاریک

- عربي

- ارمانیایی

- اذربایجاني

- باسک

- بلاروسي

- بنګالي

- بوسنیایی

- بلغاریه ایی

- کتالین

- سیبوانو

- چین

- کورسیکن

- کرواسین

- چکسلواکي

- دنمارکي

- الماني

- انګلیسي

- ایسپیرینټو

- ایستونین

- فنلینډي

- فرانسوي

- فریزیایي

- ګالیسي

- ګرجستاني

- جرمني

- یوناني

- ګجراتي

- هایتي کریول

- هوسا

- هوایی

- عبري

- نه

- میاو

- هنګري

- ایلینډیک

- ایګبو

- انډونیزین

- ایرلینډي

- ایټالیوي

- جاپاني

- جاوه ای

- کناډا

- قزاقي

- خمیر

- روانډا

- کوریایی

- کردي

- قرغیزي

- مزدوري

- لاتین

- لیتوین

- لیتوانیایی

- لوګزامبورګي

- مقدوني

- ملاګاسي

- مالایا

- ملایلم

- مالتیس

- ماوري

- مراټي

- مغولي

- میانمار

- نیپالي

- نارویژي

- نارویژي

- اوکسيټي

- پښتو

- فارسي

- پولیش

- پورتګالي

- پنجابي

- رومانیایی

- روسي

- سامواني

- سکاټلینډي ګیلیک

- صربي

- انګلیسي

- شونا

- سندي

- سينهاله

- سلواکي

- سلوانیایی

- سومالیایی

- هسپانیه ایی

- سنډانیز

- سواحلي

- سویډیش یا سویډني

- تګالوګ

- تاجک

- تامیل

- تاتار

- تولیګو

- تای

- ترکي

- ترکمني

- اوکرایني

- اردو

- اویغور

- ازبکي

- ویتنامي

- ولش

- مرسته

- یدیش

- یوروبا

- زولو

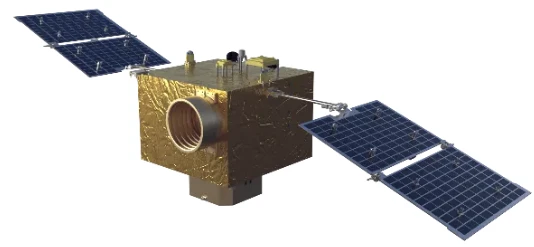

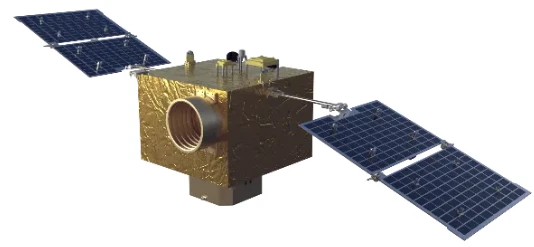

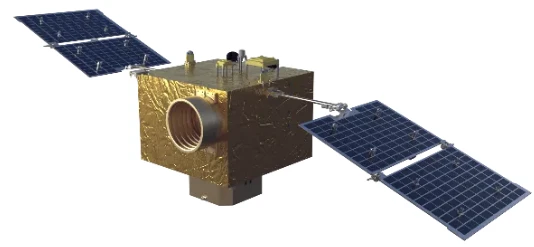

Precision in Space: Optical Profiler Applications in SpaceNavi’s Satellite Manufacturing

In the aerospace industry, where nanometers can make the difference between mission success and failure, SpaceNavi Co., Ltd. stands out by integrating high-precision metrology tools into its satellite development workflow. Among these tools, the optical profiler plays a critical role in enhancing the reliability and quality of each mission. Whether we're engineering satellite payloads, testing critical optical surfaces, or validating structural components, SpaceNavi leverages the power of advanced optical instrument systems to drive precision from the ground up.

The Role of the Optical Profiler in High-End Satellite Manufacturing

The optical profiler is an essential non-contact surface measurement device that uses light interference patterns to detect surface roughness, height variations, and texture. This level of analysis is critical when developing and polishing sensitive satellite optics, sensor mounts, and payload components.

At SpaceNavi, we use the optical profiler during multiple stages of the satellite assembly process. Whether verifying the flatness of a mirror for a remote sensing satellite or ensuring uniform coatings on an optical payload lens, this instrument enables our engineers to catch flaws before they become functional issues in orbit.

In addition, SpaceNavi applies optical surface profilometer technology to perform broader surface mapping and 3D surface characterization. Together, these tools help us uphold the highest standards for aerospace manufacturing.

Advancing Metrology with Optical Profilometer and 3D Optical Profilometer

To complement the optical profiler, SpaceNavi employs both the optical profilometer and the 3D optical profilometer in our R&D and production facilities. The optical profilometer offers rapid scanning of component surfaces to identify micro-level imperfections or deviations, ensuring exact alignment and fit during component integration.

Meanwhile, the 3D optical profilometer creates detailed surface topography with three-dimensional depth, allowing engineers to detect anomalies across complex geometries like satellite antennas or curved sensors. These instruments provide our technical teams with a complete surface insight that supports rapid development and validation, reducing production cycles without compromising performance.

This advanced level of inspection ensures that every component meets or exceeds the structural and optical criteria required for the extreme conditions of space.

Cleanroom Monitoring and Quality Assurance through Optical Particle Instruments

Cleanliness is paramount in space engineering. SpaceNavi maintains top-level cleanroom standards by incorporating the optical particle counter and optical particle sizer in our quality assurance protocols. These instruments detect, count, and analyze airborne particles that could compromise sensitive optical instrument assemblies or delicate electronic components.

The optical particle counter is used to continuously monitor cleanroom air quality, ensuring that assembly environments remain contaminant-free. In parallel, the optical particle sizer provides real-time particle distribution metrics, giving engineers precise control over environmental factors during manufacturing.

Through the integration of these optical particle systems, SpaceNavi not only protects the integrity of its optical assemblies but also reinforces its reputation for delivering durable, high-performance satellites ready for complex Earth observation, communications, and scientific missions.