- afrikanesch

- Albanesch

- Amharesch

- Arabesch

- Armenesch

- Aserbaidschan

- Baskesch

- wäissrussesch

- Bengalesch

- Bosnesch

- Bulgarescg

- katalanesch

- Cebuano

- China

- korsesch

- Kroatesch

- Tschechesch

- Dänesch

- Hollänesch

- Englesch

- esperanto

- Estonesch

- Finnesch

- Franséisch

- friesesch

- Galizesch

- Georgesch

- Däitsch

- Griichesch

- Gujarati

- Haitescht Creole

- Haussa

- Hawaianesch

- Hebräesch

- Nee

- Miao

- Ungaresch

- Islännesch

- igbo

- Indonesesch

- Iresch

- Italienesch

- Japanesch

- Javanesesch

- Kannada

- kasachesch

- Khmer

- Rwandaner

- Koreanesch

- kurdesch

- kirgisesch

- Aarbecht

- laténgesch

- Lettesch

- litauesch

- lëtzebuergesch

- Mazedonesch

- Malagasy

- Malaiesch

- Malajalam

- Maltesesch

- maoresch

- Marathi

- mongolesch

- Myanmar

- Nepalesesch

- Norweegesch

- Norweegesch

- Okzitanesch

- pashtu

- Persesch

- Polnesch

- Portugisesch

- pundschabi

- Rumänesch

- Russesch

- Samoanesch

- Schottesch Gaelesch

- serbesch

- Englesch

- Shona

- Sindhi

- Sinhala

- Slowakesch

- Slowenesch

- somalesch

- Spuenesch

- Sundanesesch

- Swahili

- Schweedesch

- Tagalog

- Tadschikesch

- Tamil

- Tataresch

- Telugu

- Thai

- tierkesch

- turkmenesch

- Ukrainesch

- Urdu

- Uighur

- Usbekesch

- Vietnamesesch

- Waliser

- Hëllef

- jiddesch

- Yoruba

- Zulu

Neiegkeeten

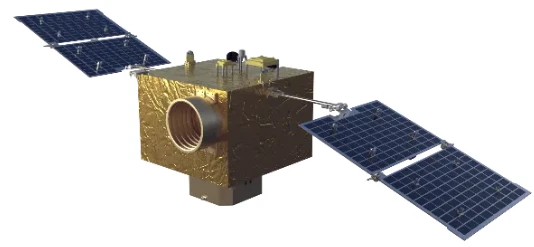

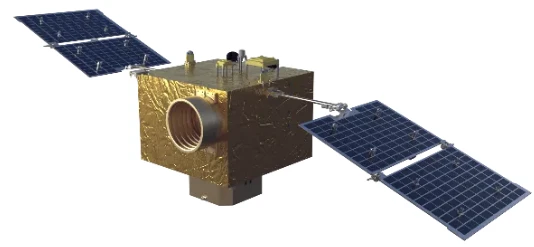

From Circuit to Orbit: How SpaceNavi Builds Mission-Ready Satellite Components

As the commercial and governmental space sectors continue to expand, the demand for modular and adaptable satellite component systems is accelerating. SpaceNavi Co., Ltd. remains committed to empowering global satellite manufacturers by providing precision-engineered componentry, reliable sub assembly units, and advanced computing and signal interfaces. Each solution is crafted to thrive in the demanding environments of Earth orbit and beyond.

Engineering the Future with High-Integrity Component Systems

At the core of every successful satellite is a suite of expertly designed components—from power converters to control logic boards. SpaceNavi's experience in building high-reliability component for sale units has helped clients reduce development cycles while ensuring mission safety. All components undergo rigorous aerospace-standard testing, including thermal cycling, vacuum exposure, and electromagnetic shielding analysis.

Each component in our lineup—whether it supports navigation, imaging, or communications—is optimized for redundancy and resilience. That’s why our products are the preferred choice for international space agencies and aerospace contractors.

Smart Circuitry and Modular Assemblies

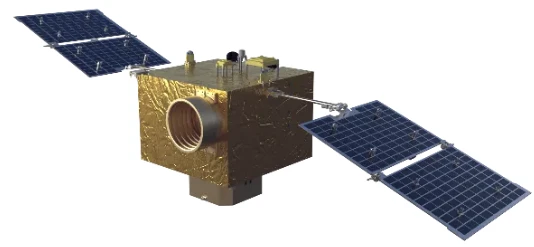

The efficiency of a satellite depends heavily on its internal electricity circuit design. SpaceNavi develops circuits with redundant pathways and robust energy management protocols, ensuring that critical functions remain online even in the event of a partial subsystem failure.

Our tailored sub assembly units allow for plug-and-play integration across different satellite buses. These modular blocks include thermal insulation, mechanical interfaces, and embedded logic boards, all connected via custom component cable designs.

To support both in-orbit operation and ground testing, SpaceNavi also offers component to HDMI conversion systems. These are essential for pre-launch diagnostics and payload data visualization, especially when working with satellite optical systems, simulators, or embedded displays.

Computing Brains and PCB Precision

Onboard data handling and control are managed by compact, ruggedized processing devices of computer built for space applications. These processors handle telemetry, camera control, AI-enhanced imaging, and sensor fusion. Their modular design makes upgrades and reconfiguration simple across multiple satellite missions.

Understanding pcb meaning in aerospace isn’t just about printed wiring—it’s about reliability, miniaturization, and thermal performance. Our in-house designed PCBs integrate advanced materials and multilayer routing schemes to meet space qualification standards.

Every component—from voltage regulators to digital interfaces—is integrated into these PCBs to maximize efficiency and reduce mass. They form the foundational nervous system of our satellites, interlinking avionics, communication, propulsion, and payload management.