- Afrikaanske

- Albaneesk

- Amhaarsk

- Arabysk

- Armeensk

- Azerbeidzjaansk

- Baskysk

- Wytrussysk

- Bengaalsk

- Bosnysk

- Bulgaarsk

- Katalaansk

- Cebuano

- Sina

- Korsikaansk

- Kroatysk

- Tsjechysk

- Deensk

- Nederlânsk

- Ingelsk

- Esperanto

- Estysk

- Finsk

- Frânsk

- Frysk

- Galyskysk

- Georgysk

- Dútsk

- Gryksk

- Gujaratysk

- Haïtiaansk Kreaolsk

- Hausa

- Hawaïaansk

- Hebrieuwsk

- Nee

- Miao

- Hongaarsk

- Yslânsk

- igbo

- Yndonesysk

- Iersk

- Italiaansk

- Japansk

- Javaansk

- Kannada

- Kazachsk

- Khmer

- Rwandan

- Koreaansk

- Koerdysk

- Kirgizysk

- Arbeid

- Latyn

- Letsk

- Litousk

- Lúksemboarchsk

- Masedoanysk

- Malagasy

- Maleisk

- Malayalam

- Malteesk

- Maori

- Maratysk

- Mongoalsk

- Birma

- Nepaleesk

- Noarsk

- Noarsk

- Oksitaansk

- Pashtu

- Perzysk

- Poalsk

- Portegeesk

- Pûndjaabsk

- Roemeensk

- Russysk

- Samoan

- Skotsk Gaelic

- Servysk

- Ingelsk

- Shona

- Sindysk

- Sinhala

- Slowaaksk

- Sloveensk

- Somalysk

- Spaansk

- Soendaneesk

- Swahily

- Sweedsk

- Tagaloch

- Tajik

- Tamyl

- Tatar

- Telugu

- Taisk

- Turksk

- Turkmeensk

- Oekraynsk

- Urdu

- Uighur

- Uzbek

- Fietnameesk

- Welsh

- Help

- Jiddysk

- Yoruba

- Zulu

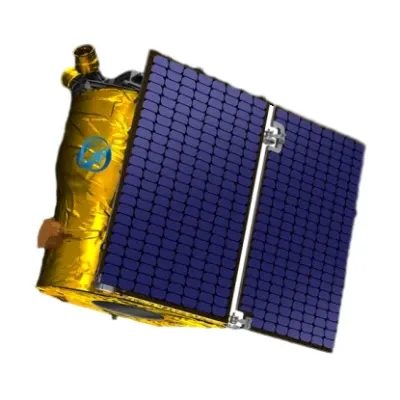

Aerospace Innovation Through Every Component For Sale

In the aerospace and satellite industries, every detail matters. From control modules to power distribution units, each component plays a pivotal role in mission success. At SpaceNavi Co., Ltd., our commitment to innovation begins at the smallest level—with the intelligent design, manufacturing, and integration of high-performance components tailored for space-based applications.

In an industry where reliability is non-negotiable, our engineering team ensures that each component for sale meets the rigorous standards of modern aerospace technology. By aligning advanced materials with precision assembly, SpaceNavi delivers not only parts—but dependable performance at every orbital stage.

Understanding The Heart of Technology: PCB Meaning in Aerospace

In the context of space systems, pcb meaning goes far beyond “printed circuit board.” It reflects the nerve center of onboard electronics, linking everything from propulsion controls to communication arrays. Our aerospace-grade PCBs are designed for resilience, low-noise operation, and durability under the extreme conditions of launch and orbit.

Whether operating in high-radiation environments or under varying thermal loads, SpaceNavi’s circuit solutions provide consistent connectivity and performance. We emphasize insulation, layout precision, and custom layering to fit the structural constraints of satellite platforms—ensuring every board fits seamlessly into the broader componentry of our spacecraft.

From Sub Assembly to Full Integration

At SpaceNavi, we understand that a mission-ready spacecraft is built from carefully tested and qualified subsystems. That’s why we place a strong emphasis on sub assembly units, including guidance controls, telemetry transmitters, and attitude adjustment modules.

These components are assembled, tested, and validated as stand-alone units before final integration, ensuring every function works under independent and interdependent conditions. Our componentry approach focuses on modularity, meaning clients can scale, customize, or swap parts depending on mission requirements.

As part of our mission integration services, we also provide detailed layout planning for electricity circuit designs, balancing power efficiency with stability across critical systems. Each power unit, connector, and fuse path is mapped with precision to minimize potential interference and optimize operational endurance.

Aerospace-Ready Connectivity: Component Cable and Beyond

Robust data and power transmission are vital in satellite missions. From interior connections to ground communication interfaces, SpaceNavi offers aerospace-certified component cable systems and interfaces. These connectors are resistant to vibration, electromagnetic interference, and thermal fluctuations.

Additionally, with the growing convergence between aerospace systems and commercial display technologies, we support interface solutions such as component to HDMI conversions. These help mission teams monitor payload data and satellite diagnostics on modern screens without data loss or conversion lag.

This cross-compatibility supports enhanced mission control and payload visualization on Earth, extending our aerospace capabilities into everyday operational tools.

SpaceNavi: A Name Behind Every Critical Komponint

Behind every successful launch lies a series of calculated decisions—about design, materials, structure, and function. At Spaceships, we recognize that the smallest part can determine the outcome of an entire mission. That's why our philosophy is simple: design every component as if it's mission-critical—because it is.

Through low-cost, high-efficiency design and short production cycles, we ensure our partners, including government agencies and international aerospace companies, receive the customized support they need. Whether you're sourcing a component for sale, testing a new sub assembly, or building the backbone of an onboard electricity circuit, SpaceNavi stands ready with the expertise and infrastructure to help you succeed.

SpaceNavi’s innovation isn't just seen in satellites—it’s embedded in every cable, every connector, every circuit. Our componentry is built for the sky but grounded in trust.