Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Advanced Satellite Platform for Enhanced Operational Efficiency

Introduction to Advanced Satellite Platforms

In the rapidly evolving aerospace industry, the satellite platform serves as the foundational infrastructure for a multitude of space-based missions. It encompasses the core structural, power, propulsion, thermal, and attitude control systems that enable a satellite to operate effectively in orbit. From scientific research to defense and commercial applications, the robustness and technological sophistication of a satellite platform directly influence mission success and data integrity. This article delves into the critical aspects of modern satellite platforms, exploring their intricate manufacturing processes, technical advantages, diverse applications, and the industry's drive towards enhanced operational efficiency.

The demand for high-resolution imagery and sophisticated data collection has significantly elevated the requirements for satellite systems. These platforms are engineered to support payloads that can capture detailed imagery, conduct advanced remote sensing, and facilitate global communication, making them indispensable assets for both governmental and private entities. Understanding the nuances of these complex systems is paramount for decision-makers in target industries like petrochemical, metallurgy, and water supply & drainage, where precision and reliability are non-negotiable.

Industry Trends in Satellite and Remote Sensing Technology

The satellite industry is experiencing unprecedented growth, driven by several key trends. Miniaturization and constellation deployment are revolutionizing access to space, making satellite data more ubiquitous and affordable. The global remote sensing market size was valued at USD 14.0 billion in 2023 and is projected to reach USD 30.6 billion by 2030, growing at a CAGR of 11.9% (Source: Grand View Research). This expansion is fueled by innovations in sensor technology, artificial intelligence for data processing, and the increasing demand for real-time geospatial intelligence across various sectors.

Another significant trend is the push for higher resolution and faster revisit times. High-resolution imagery, such as that provided by the GF Series Satellites with a resolution of 0.5m, is crucial for detailed monitoring, urban planning, disaster response, and security applications. The integration of advanced onboard processing capabilities and inter-satellite communication links is also enhancing data delivery speeds and improving overall operational efficiency. Furthermore, the development of software-defined satellites and reconfigurable payloads allows for greater flexibility and adaptability to evolving mission requirements, reducing costs and extending the useful life of space assets.

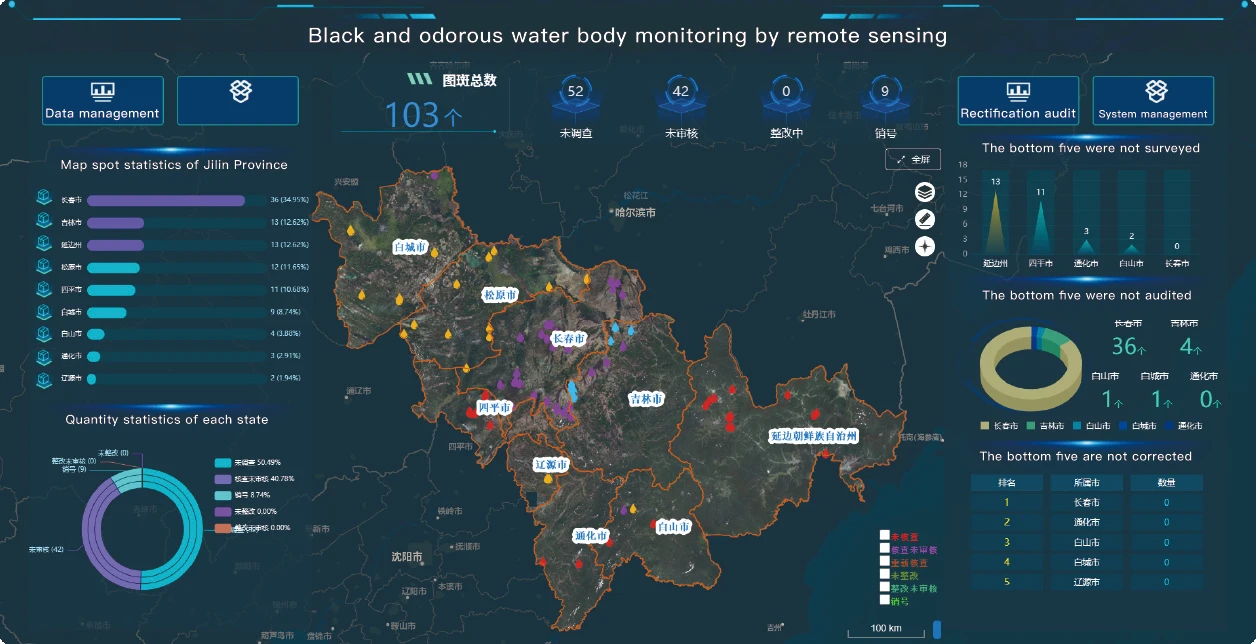

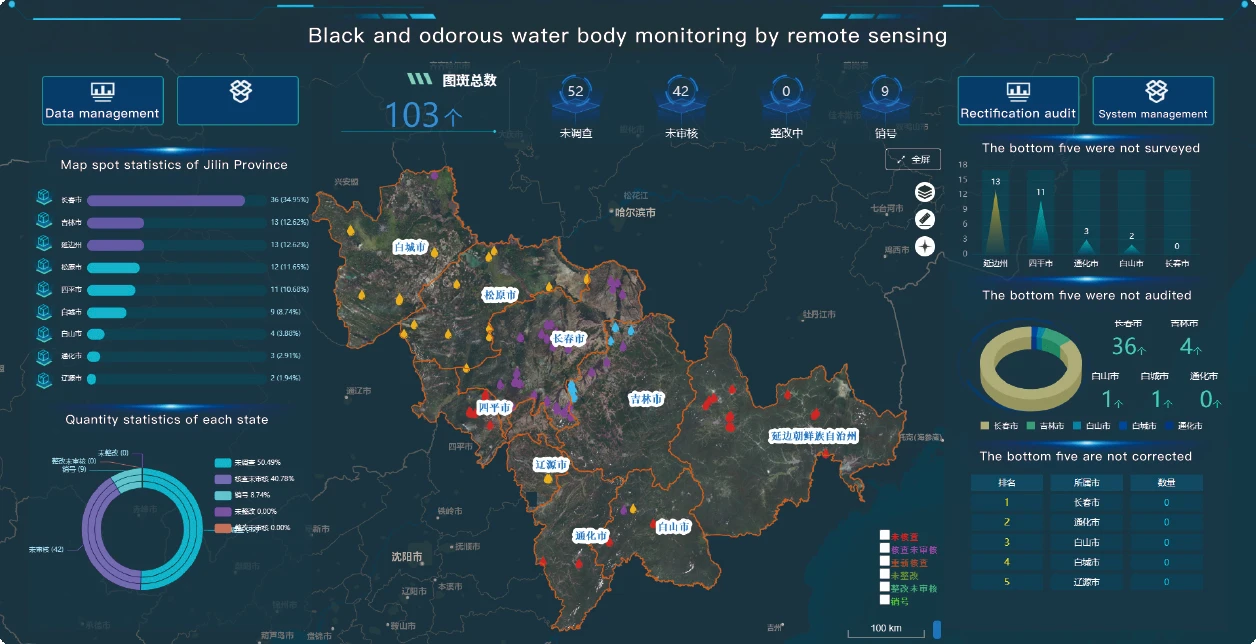

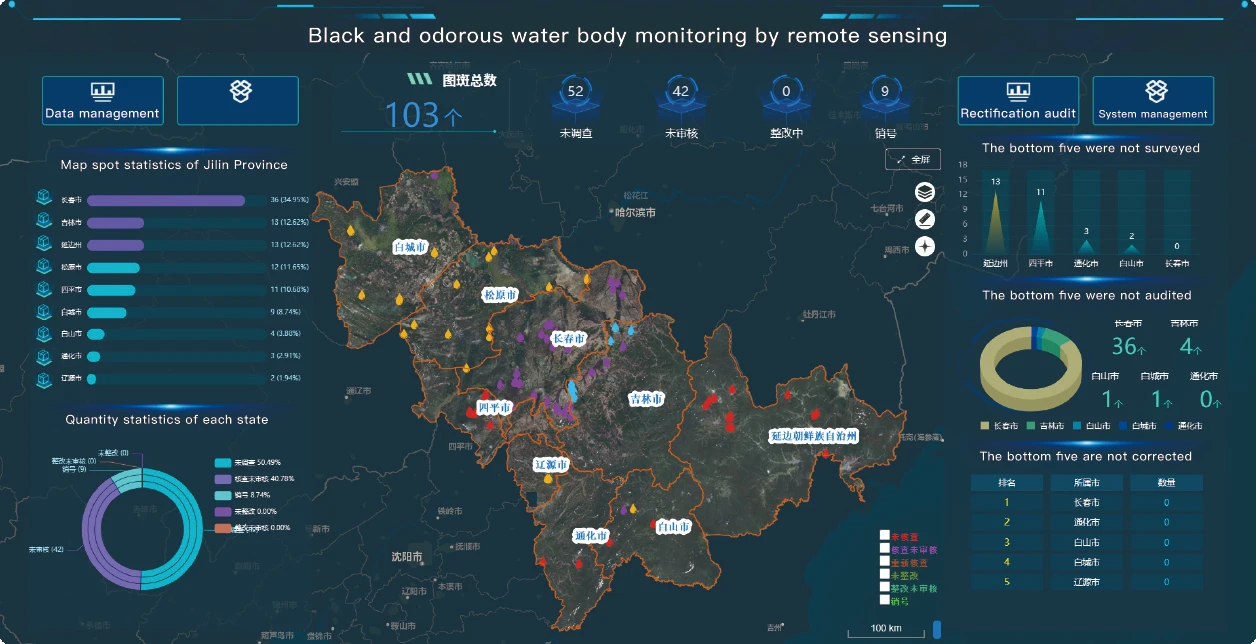

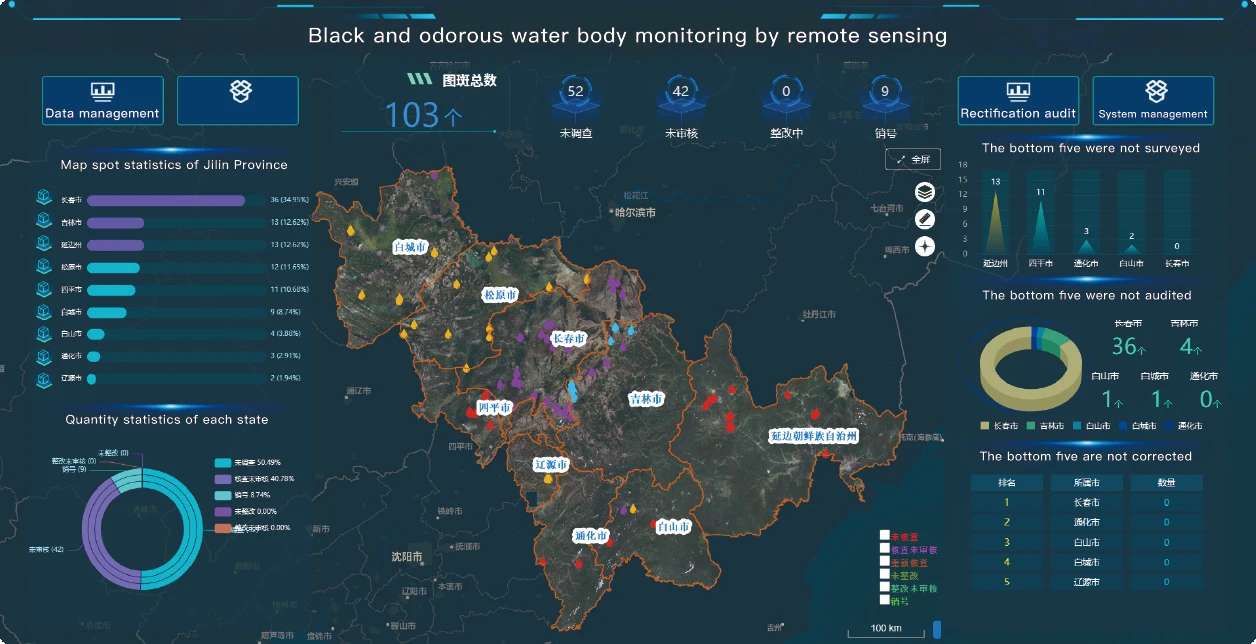

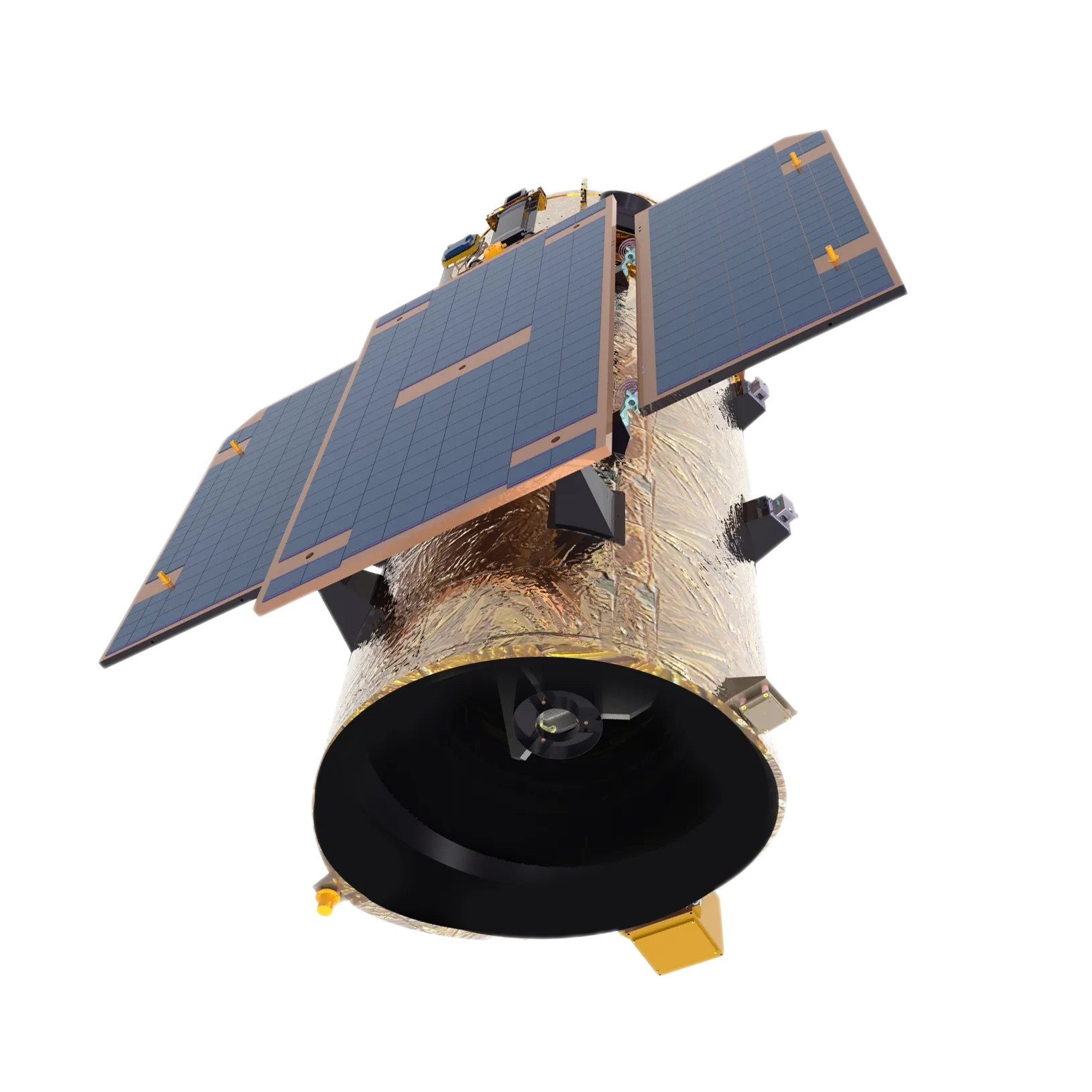

Image: GF Series Satellite, a testament to modern satellite platform engineering.

Technical Specifications: GF Series Satellites With A Resolution Of 0.5m

The GF Series Satellites exemplify cutting-edge satellite technology, offering unparalleled resolution and robust performance for demanding applications. These platforms are designed to provide high-fidelity imagery and data, critical for detailed analysis and strategic decision-making. The core technical specifications highlight the advanced engineering involved in their construction and operation.

Product Specification Table: GF Series Satellite Platform

| Parameter | Specification |

|---|---|

| Orbital Altitude | Approximately 500-700 km (Sun-synchronous orbit) |

| Resolution (Panchromatic) | 0.5 meters |

| Resolution (Multispectral) | 2 meters |

| Swath Width | >60 km |

| Revisit Time | Daily (or better, depending on constellation size) |

| Data Storage Capacity | Up to 2 TB onboard |

| Downlink Speed | X-band, >1 Gbps |

| Payload Capacity | Supports various high-resolution optical instruments |

| Service Life | 7+ years (designed for longevity) |

| Attitude Control System Accuracy | <0.01 degrees (pointing accuracy) |

The robust design of the GF Series satellite platform ensures exceptional reliability and performance throughout its operational lifespan. Its high resolution capabilities make it suitable for detailed urban mapping, infrastructure monitoring, environmental assessment, and advanced intelligence gathering, solidifying its position as a leader in remote sensing applications.

Manufacturing Process of a Satellite Platform

The construction of a modern satellite platform is an incredibly complex and precise undertaking, involving multi-disciplinary engineering and adherence to stringent quality controls. The process ensures that each component can withstand the harsh conditions of space, from launch vibrations to extreme temperature fluctuations and radiation.

Key Stages in Satellite Platform Manufacturing:

- Design and Simulation: This initial phase involves extensive computer-aided design (CAD) and finite element analysis (FEA) to simulate structural integrity, thermal behavior, and vibrational responses. Materials like carbon fiber composites, aluminum alloys (e.g., Al 6061-T6, Al 7075-T6), and titanium are selected for their high strength-to-weight ratio, thermal stability, and radiation resistance.

-

Component Manufacturing:

- Structural Elements: Fabrication of load-bearing structures often employs advanced manufacturing processes such as additive manufacturing (3D printing for complex geometries), CNC machining for high-precision components, and specialized forging/casting for critical parts.

- Propulsion Systems: Manufacturing of thrusters, fuel tanks, and associated plumbing requires precision welding and sealing techniques for handling hypergolic or electric propellants. Materials must be compatible with highly reactive chemicals.

- Power Systems: Solar panels are meticulously assembled, often using multi-junction gallium arsenide (GaAs) cells for maximum efficiency. Battery packs utilize space-grade Lithium-ion cells, requiring robust thermal management.

- Avionics & Control: Electronic components are manufactured in cleanroom environments to prevent contamination. Micro-fabrication techniques are used for advanced sensors and processors.

- Assembly and Integration: Subsystems are integrated in a cleanroom. This includes meticulous cabling, connector installation, and precise alignment of optical components. The assembly process is highly iterative, with continuous verification.

-

Testing and Verification: This is the most critical phase for ensuring reliability and validating the design against mission requirements.

- Vibration Testing: Simulates launch loads (e.g., sine, random, shock) to ensure structural integrity. Adheres to standards like ISO 19683 (Space Systems – General Test Methods for Space-Borne Equipment).

- Thermal Vacuum Testing (TVAC): Exposes the satellite to extreme temperature cycles and vacuum conditions, replicating the space environment, often following ECSS-E-ST-10-03C (Space engineering – Testing) guidelines.

- Electromagnetic Compatibility (EMC/EMI): Ensures all electronic systems operate without interference. Compliance with MIL-STD-461 or equivalent is common.

- Functional Testing: Comprehensive end-to-end testing of all subsystems (power, communication, attitude control, payload) to verify operational performance.

- Pre-launch Preparation: Final checks, propellant loading (if applicable), and encapsulation within the launch vehicle fairing.

Target Industries and Advantages:

The robust design and rigorous testing protocols of a high-quality satellite platform ensure a service life of 7+ years, providing long-term value. This makes them ideal for industries requiring consistent and reliable data.

- Petrochemical: Monitoring of pipelines, oil fields, and refinery infrastructure for environmental compliance, leak detection, and security. The remote sensing capabilities contribute to proactive maintenance, reducing risks and improving operational efficiency.

- Metallurgy: Earth observation data for mineral exploration, monitoring of mining operations, and environmental impact assessment of industrial sites. High-resolution imagery supports site planning and resource management.

- Water Supply & Drainage: Tracking water resources, monitoring dam integrity, detecting illegal waste disposal, and managing urban drainage systems. This contributes to resource preservation and infrastructure safety.

- Agriculture & Forestry: Crop health monitoring, yield prediction, deforestation tracking, and precision farming applications for optimized resource use.

- Disaster Management: Rapid assessment of damage after natural calamities (floods, earthquakes, wildfires) to aid rescue and recovery efforts, significantly enhancing response operational efficiency.

The materials and processes chosen are specifically designed for properties like corrosion resistance, essential for maintaining structural integrity in the presence of atmospheric residues before launch, and radiation hardening in orbit, directly impacting the service life and reliability of the overall satellite system. The intrinsic advantages, such as superior energy saving through efficient power management systems and minimized heat dissipation, directly translate to lower operational costs and enhanced longevity.

Application Scenarios and Technical Advantages

The versatility of advanced satellite platform designs, particularly those optimized for high-resolution remote sensing, unlocks a myriad of application scenarios across diverse B2B sectors. These platforms provide critical data that enhances decision-making, streamlines operations, and offers competitive advantages.

Key Application Scenarios:

- Infrastructure Monitoring: Precision monitoring of large-scale infrastructure projects like dams, bridges, roads, and power grids. High-resolution imagery can detect subtle structural changes, ground subsidence, or unauthorized construction, enabling predictive maintenance and preventing costly failures. For instance, monitoring a 1000 km oil pipeline in remote terrain for potential leaks or encroachments can reduce inspection costs by 70% compared to traditional aerial surveys.

- Environmental Stewardship: Detailed assessment of deforestation, land-use change, coastal erosion, and glacier melt. Specialized sensors can monitor water quality, air pollution, and track wildlife migrations, supporting environmental compliance and conservation efforts.

- Urban Planning and Development: Comprehensive mapping of urban growth, traffic flow analysis, and site selection for new developments. The ability to update maps frequently ensures planners have the most current data, leading to more efficient resource allocation.

- Defense and Intelligence: Surveillance, reconnaissance, and intelligence gathering for national security purposes. The 0.5m resolution offers sufficient detail for identifying military assets, tracking movements, and assessing strategic locations.

Technical Advantages:

- Superior Resolution and Image Quality: With 0.5m panchromatic resolution, the GF Series provides detail previously only achievable by aerial platforms, but with global coverage and reduced operational costs. This clarity is crucial for precise feature extraction and change detection.

- Enhanced Revisit Capabilities: Advanced orbital mechanics and potential for constellation deployment enable frequent revisits, providing near-real-time monitoring crucial for dynamic environments and rapid response scenarios.

- Robust Data Processing and Transmission: Onboard processing capabilities minimize data latency, while high-speed X-band downlinks ensure efficient delivery of large datasets to ground stations. This significantly improves data availability and operational efficiency for end-users.

- Long Service Life and Reliability: Designed for an extended operational lifespan (7+ years), these satellite systems minimize the total cost of ownership and ensure continuous data flow without frequent replacement. This is a direct result of stringent material selection, robust manufacturing processes, and comprehensive testing, ensuring corrosion resistance and resistance to space environment degradation.

- Energy Efficiency: Optimized power generation and distribution systems, coupled with advanced thermal management, lead to reduced power consumption and higher reliability, contributing to overall mission success and longevity. This translates to lower ongoing operational costs.

Vendor Comparison: Evaluating Satellite Platform Providers

Choosing the right satellite platform vendor requires careful consideration of various factors beyond just technical specifications. Reliability, support, customization options, and track record are paramount for B2B clients making significant long-term investments.

Comparison Factors for Satellite Platforms:

- Payload Flexibility: The ability of the platform to accommodate various types of sensors and instruments, crucial for multi-mission capability.

- Scalability: Ease of expanding a constellation or upgrading individual satellites in the future.

- Manufacturing Excellence & QA: Adherence to international standards (e.g., ISO 9001 for quality management, AS9100 for aerospace manufacturing) and proven robust testing protocols (e.g., ECSS standards).

- Mission Longevity & Reliability: Track record of satellites meeting or exceeding their design life. Mean Time Between Failures (MTBF) data is a key indicator.

- Ground Segment & Data Services: Availability of comprehensive ground infrastructure and robust data processing, archival, and delivery services.

- Cost-Effectiveness: Balancing initial investment with long-term operational costs and data value.

Generic Satellite Platform Comparison Table:

| Feature | Provider A (e.g., GF Series) | Provider B (Typical Market Offering) | Provider C (Emerging Player) |

|---|---|---|---|

| Panchromatic Resolution | 0.5 meters | 0.8 - 1.5 meters | 1.5 - 3.0 meters |

| Multispectral Resolution | 2 meters | 3 - 6 meters | 5 - 10 meters |

| Revisit Frequency | Daily (or better with constellation) | 1-3 days | 3-7 days |

| Designed Service Life | 7+ years | 5 years | 3-5 years |

| Payload Adaptability | High (modular design) | Medium | Limited |

| Certification Standards | ISO 9001, AS9100, ECSS-compliant testing | ISO 9001 | Internal QA |

This comparison highlights that providers like those behind the GF Series prioritize superior resolution, longer service life, and adherence to rigorous certification standards, delivering a higher value proposition in terms of data quality and reliability for demanding remote sensing missions. Such factors are crucial for achieving long-term operational efficiency and maximizing ROI.

Customized Solutions and Application Case Studies

While standard satellite platform offerings provide a solid foundation, many B2B clients require tailored solutions to meet unique mission objectives. Customization can involve specific payload integration, orbital parameters, data processing algorithms, or ground segment interfaces.

Customization Options:

- Payload Configuration: Integrating client-specific sensors (e.g., advanced hyperspectral imagers, synthetic aperture radar, specialized communication transponders) onto the GF Series satellite platform. This ensures the platform is perfectly matched to the application's data requirements.

- Orbit and Constellation Design: Adjusting orbital parameters (e.g., altitude, inclination) to optimize revisit times or coverage for specific geographic areas. For large-scale monitoring, designing and deploying a constellation of GF Series satellites can provide near-continuous coverage.

- Data Processing and Delivery: Developing bespoke software tools for automated feature detection, change analysis, or integration with existing client GIS (Geographic Information System) platforms. Secure, dedicated data links can also be established.

- Ground Segment Integration: Providing support for integrating the satellite operations with the client's existing ground control infrastructure or setting up dedicated ground stations.

Application Case Studies (Experience & Authoritativeness):

Our extensive experience in deploying robust satellite solutions has enabled partners to achieve significant operational efficiency and critical insights.

-

Case Study 1: Large-Scale Infrastructure Monitoring (Petrochemical Sector)

A leading global energy company sought a solution for comprehensive, real-time monitoring of its vast network of oil and gas pipelines across challenging terrains. Utilizing a customized constellation of GF Series-derived satellite platform units, we provided daily high-resolution imagery. This enabled the client to detect subtle land deformations indicative of potential pipeline stress, identify unauthorized construction near critical infrastructure, and monitor environmental impacts. Initial feedback indicated a 40% reduction in manual inspection costs and a 25% improvement in proactive maintenance scheduling, significantly enhancing asset security and compliance. -

Case Study 2: Agricultural Resource Management (Government Agency)

A national agricultural agency required precise data for crop yield prediction and drought monitoring. We deployed a GF Series satellite configured with specific multispectral bands optimized for vegetation indices (e.g., NDVI, EVI). The high-frequency data allowed the agency to create detailed maps of crop health at regional and local scales, identify stress factors early, and allocate irrigation resources more effectively. This led to an estimated 15% increase in average crop yield for participating farms and improved national food security planning. Customer feedback highlighted the "unprecedented detail and timeliness" of the data as a game-changer for their policy formulation. -

Case Study 3: Urban Development & Environmental Impact Assessment (Municipal Government)

A rapidly growing metropolis needed continuous updates on urban sprawl and environmental changes to guide sustainable development. Our customized satellite platform provided weekly 0.5m resolution imagery, enabling the city planning department to track new construction, informal settlements, and changes in green spaces. This data was integrated into their GIS, streamlining permitting processes and allowing for more accurate environmental impact assessments. The city reported a 30% acceleration in project evaluation cycles and improved accountability in land-use changes.

Commitment to Trustworthiness: FAQ, Fulfillment, Warranty & Support

Frequently Asked Questions (FAQ):

- Q1: What makes the GF Series satellite platform ideal for B2B applications?

- A1: The GF Series combines industry-leading 0.5m resolution with robust construction, ensuring high-fidelity data and a long service life. Its modular design allows for customization to specific payloads and mission requirements, making it highly adaptable for diverse commercial and governmental applications demanding precision remote sensing.

- Q2: What is the typical lead time for a customized GF Series satellite?

- A2: Lead times vary based on the level of customization and current production schedules. For a standard GF Series unit with minor payload integration, the lead time is typically 18-24 months from contract signing to launch readiness. Complex, multi-satellite constellations or highly specialized payloads may require longer lead times, which are clearly defined in the project timeline.

- Q3: How is data security and privacy ensured?

- A3: We implement stringent security protocols at every stage, from secure data encryption during transmission (AES-256) to access-controlled ground stations and robust data storage solutions. Client data is handled with the utmost confidentiality, adhering to international data protection regulations and specific client-defined security requirements.

- Q4: What environmental standards does your manufacturing process adhere to?

- A4: Our manufacturing facilities are ISO 14001 certified for environmental management. We prioritize sustainable practices, including waste reduction, energy efficiency, and responsible material sourcing, throughout the entire lifecycle of the satellite platform components.

Lead Time and Fulfillment:

Our streamlined project management and robust supply chain ensure predictable and reliable fulfillment. Standard satellite platform deliveries are typically completed within 18-24 months for individual units. For constellation projects, phased deliveries are planned to meet operational timelines. Each project includes a detailed fulfillment schedule, risk assessment, and regular progress reporting to ensure transparency and client confidence. We operate globally, with logistics partners specialized in aerospace transport, guaranteeing safe and timely delivery to launch sites.

Warranty Commitments:

We offer a comprehensive warranty for the GF Series satellite platform, covering manufacturing defects and ensuring performance against agreed-upon specifications for the expected operational lifespan (typically 7 years). Our warranty terms are designed to provide peace of mind, backed by our commitment to engineering excellence and rigorous testing. Full details of the warranty, including scope and exclusions, are provided in the contractual agreement for each project.

Customer Support:

Our dedication to client success extends far beyond delivery. We provide 24/7 technical support from a team of experienced satellite engineers and operations specialists. This includes assistance with ground segment integration, mission planning, data processing, and troubleshooting. Clients have access to dedicated account managers, comprehensive documentation, and regular training programs to maximize the value and operational efficiency of their remote sensing assets. Emergency support protocols ensure rapid response to any critical issues.

Conclusion

The modern satellite platform, as exemplified by the GF Series, stands as a pinnacle of engineering achievement, driving innovation across numerous industries. Its advanced technical specifications, coupled with rigorous manufacturing processes and a commitment to longevity, position it as a critical asset for high-stakes remote sensing and data acquisition missions. From ensuring the operational efficiency of global petrochemical networks to enhancing agricultural productivity and bolstering national security, these platforms deliver unparalleled insights. By embracing cutting-edge trends and offering tailored solutions, vendors are continuously pushing the boundaries of what is possible in space, providing indispensable tools for a data-driven world.

References

- Grand View Research. (2023). Remote Sensing Market Size, Share & Trends Analysis Report.

- ISO 19683:2018. (2018). Space systems — General test methods for space-borne equipment. International Organization for Standardization.

- ECSS-E-ST-10-03C Rev.1. (2020). Space engineering – Testing. European Cooperation for Space Standardization.

- Space Foundation. (2023). The Space Report 2023 Q3.

- NASA. (2024). Earth Observing System Data and Information System (EOSDIS) standards.