- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

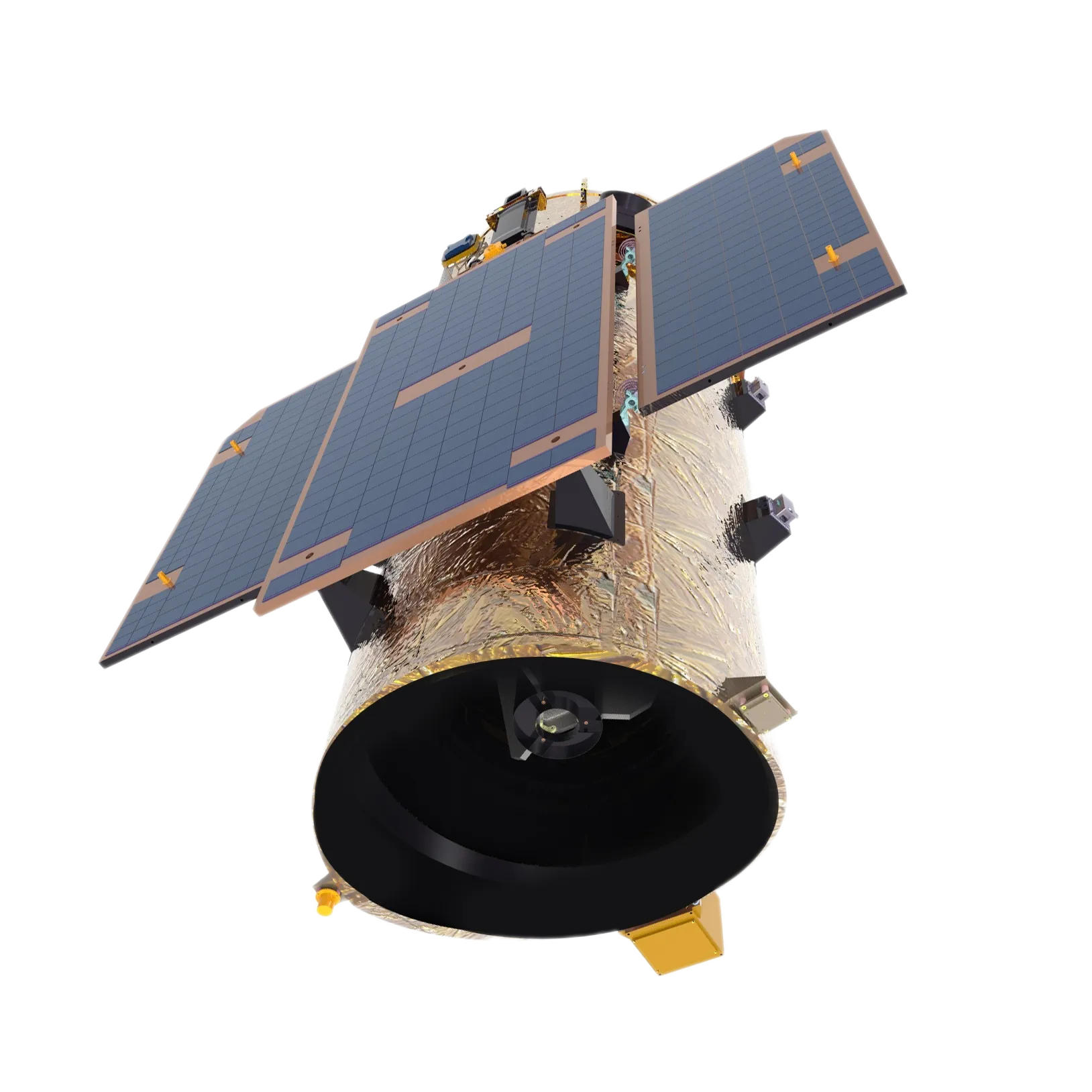

Precision Environmental Data for Water & Land Insights

The Imperative of Accurate Environmental Data in Modern Water Management

In an era defined by rapid climate shifts and escalating demand for finite resources, the precise acquisition and analysis of environmental data have become indispensable for sustainable water conservancy. From mitigating the impacts of water pollution detection to understanding complex land cover change dynamics, reliable environmental data forms the bedrock of informed decision-making. Our flagship offerings, under the umbrella of Water Conservancy Products And Services, are engineered to meet these critical needs, providing unparalleled accuracy in data acquisition with high spatial resolution.

Industry Trends: The Evolving Landscape of Environmental Data Collection

The global focus on climate change and sustainable development has significantly amplified the demand for comprehensive environmental data. Emerging trends highlight a shift towards integrated monitoring systems, leveraging advanced technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and high-resolution remote sensing. These technologies enable continuous, real-time data acquisition across vast and challenging terrains, moving beyond traditional sporadic sampling. For instance, the advent of micro-sensor networks allows for pervasive water pollution detection at previously unachievable scales, providing immediate alerts for contamination events. Furthermore, satellite imagery, combined with ground-truthing, offers unprecedented insights into land cover change, crucial for hydrological modeling and urban planning. The convergence of these technologies is not merely about collecting more data, but about generating actionable intelligence to manage water resources more effectively and mitigate environmental risks. This holistic approach to environmental data management is critical for compliance with stricter environmental regulations and achieving global sustainability goals, driving innovation in sensor technology, data transmission, and analytical platforms.

Another significant trend is the democratization of environmental data, with initiatives promoting open data access and citizen science. This necessitates robust, user-friendly, and reliable data collection tools. The demand for systems that can operate autonomously, minimize human intervention, and deliver high-fidelity data in diverse environments (from pristine natural reserves to industrial discharge points) continues to grow. These systems must also be adaptable to different parameters, whether it's monitoring dissolved oxygen levels in rivers, detecting heavy metals in groundwater, or assessing vegetation health in catchment areas. The integration of advanced analytics, including machine learning algorithms, further transforms raw environmental data into predictive models, enabling proactive management strategies for issues like flood prediction, drought monitoring, and water quality degradation. This shift from reactive to proactive environmental management is a cornerstone of modern water conservancy practices.

Technical Parameters & Capabilities for Advanced Environmental Data Collection

Our Water Conservancy Products And Services are designed with cutting-edge technical specifications to ensure superior data acquisition capabilities. Key parameters include:

- Sensor Array Versatility: Capable of integrating a wide range of smart sensors for various parameters, including pH, ORP, Conductivity, Dissolved Oxygen (DO), Turbidity, Chlorophyll, Blue-Green Algae, Nitrates, Phosphates, COD/BOD, and heavy metals. Each sensor boasts specific ranges and accuracies optimized for water body analysis.

- Spatial Resolution: Our remote sensing components (e.g., UAV-mounted LiDAR and hyperspectral cameras) offer sub-meter spatial resolution for detailed land cover change mapping and topographic analysis, crucial for understanding hydrological flows and erosion patterns.

- Temporal Resolution: Continuous monitoring platforms provide real-time environmental data updates at intervals as frequent as every minute, enabling rapid response to anomalous events like pollution spills.

- Accuracy & Precision: Our instruments adhere to stringent calibration protocols, delivering data with typical accuracies of ±1% to ±5% of the full scale, depending on the parameter, ensuring high confidence in collected environmental data. For instance, our pH sensors typically offer ±0.02 pH units accuracy.

- Robust Communication Protocols: Supporting 4G/5G, LoRaWAN, Satellite (Iridium/Inmarsat), and Wi-Fi for reliable data transmission from remote or challenging environments to central monitoring stations.

- Power Efficiency: Designed for low power consumption, allowing for extended deployment periods (months to years) on solar power or battery packs, critical for remote installations.

- Environmental Durability: Housings rated IP67/IP68, constructed from marine-grade stainless steel (e.g., 316L) and specialized engineering plastics, ensuring resilience against harsh weather, corrosive waters, and biological fouling. Operating temperature ranges from -20°C to +70°C.

Key Environmental Data Parameters & Measurement Capabilities

Application Scenarios: Where Environmental Data Makes a Difference

Our Water Conservancy Products And Services provide critical environmental data across diverse sectors, fostering sustainable resource management and risk mitigation. The versatility of our solutions enables their deployment in a multitude of scenarios:

- River & Lake Monitoring: Continuous water pollution detection, tracking of water levels, flow rates, and water quality parameters to assess ecosystem health and manage water abstractions. This includes monitoring for nutrient loading, harmful algal blooms, and industrial discharge impacts, providing early warnings for potential ecological disasters.

- Wastewater Treatment Plants (WWTPs): Optimizing treatment processes through real-time monitoring of influent and effluent quality, ensuring compliance with discharge regulations and improving operational efficiency. Parameters like BOD, COD, and suspended solids are continuously tracked to fine-tune aeration and chemical dosing, leading to significant energy savings and reduced chemical consumption.

- Drinking Water Supply: Safeguarding public health by monitoring source water quality, treatment efficacy, and distribution network integrity. Early detection of contaminants, such as heavy metals or pathogens, is paramount, achieved through precise data acquisition and rapid analysis, ensuring potable water supplies.

- Agricultural Water Management: Optimizing irrigation schedules based on soil moisture, nutrient levels, and crop water demand, leading to significant water conservation and improved crop yields. Satellite-derived land cover change data can also inform land use planning to minimize agricultural runoff pollution.

- Disaster Preparedness & Response: Real-time flood monitoring, drought assessment, and landslide risk analysis utilizing a combination of ground-based sensors and remote sensing. Our systems provide critical environmental data for early warning systems, enabling timely evacuations and efficient resource deployment during emergencies. This includes monitoring river levels, rainfall intensity, and soil saturation, which are vital for predicting and responding to extreme weather events.

- Coastal & Marine Environments: Tracking ocean currents, salinity, temperature, and pollutant dispersion to protect marine ecosystems, support aquaculture, and manage coastal erosion. This extends to monitoring the impact of climate change, such as sea-level rise and ocean acidification, through long-term environmental data series.

- Industrial Water Usage: For sectors like petrochemicals and metallurgy, accurate environmental data ensures compliance with stringent discharge limits, identifies opportunities for water recycling, and prevents costly penalties. Our solutions offer robust chemical resistance, ideal for aggressive industrial effluents, guaranteeing long-term reliability and precise monitoring.

In each of these scenarios, the ability to collect high-fidelity, actionable environmental data empowers stakeholders to make informed decisions, ensuring the longevity and health of our precious water resources.

Technical Advantages of Our Environmental Data Solutions

Our Water Conservancy Products And Services offer distinct technical advantages that set them apart in the market, ensuring superior performance and reliability in environmental data collection:

- Modular Design & Scalability: Our systems feature a modular architecture, allowing for easy integration of new sensors and expansion of monitoring capabilities as requirements evolve. This future-proof design ensures long-term applicability and cost-effectiveness.

- Advanced Sensor Technology: We utilize state-of-the-art optical, electrochemical, and acoustic sensors that provide higher accuracy, reduced calibration frequency, and extended lifespan compared to traditional probes. For instance, our optical DO sensors eliminate membrane fouling issues common with galvanic/polarographic sensors.

- Robust Data Analytics Platform: Beyond mere data acquisition, our integrated software platform offers real-time data visualization, trend analysis, anomaly detection, and predictive modeling using machine learning algorithms. This transforms raw environmental data into actionable insights.

- Energy Efficiency: Designed for remote and autonomous operation, our systems incorporate intelligent power management, low-power components, and efficient solar charging solutions, guaranteeing continuous operation even in off-grid locations for extended periods.

- Durability and Corrosion Resistance: Product components, particularly those exposed to water, are meticulously crafted from premium materials like marine-grade 316L stainless steel, titanium alloys, and advanced engineering polymers (e.g., PVDF, PEEK). This ensures exceptional resistance to corrosion, abrasion, and bio-fouling, critical for extended lifespan and consistent performance in aggressive aquatic environments.

- Compliance and Certification: All products adhere to rigorous international standards such as ISO 9001:2015 for quality management, and specific components meet ANSI, API, and ASTM standards where applicable. This commitment to standards ensures reliability and interoperability.

- Minimal Maintenance & Long Lifespan: Thanks to durable materials, self-cleaning mechanisms (for certain sensors), and robust construction, our products require minimal maintenance, significantly reducing operational costs and maximizing uptime. The typical design life for our critical sensing units ranges from 5 to 10 years, with housings often exceeding 15 years.

- Enhanced Security: Data transmission is encrypted, and access to the monitoring platform is secured with multi-factor authentication, ensuring the integrity and confidentiality of sensitive environmental data.

Manufacturing Process: Ensuring Precision in Environmental Data Equipment

The reliability and accuracy of our Water Conservancy Products And Services, essential for precise environmental data collection, stem from a meticulously engineered manufacturing process. Every step, from raw material selection to final testing, is governed by stringent quality control protocols, ensuring each product meets the highest industry standards.

Detailed Process Flow:

Step 1: Raw Material Sourcing & Inspection

We begin by sourcing premium-grade raw materials. For components exposed to harsh aquatic environments, this includes marine-grade 316L Stainless Steel, specialized corrosion-resistant polymers (e.g., PVDF, PTFE for sensor bodies, PEEK for internal components), and high-purity glass for optical sensors. All incoming materials undergo rigorous inspection, including spectroscopic analysis for material composition, mechanical testing for strength and hardness, and visual inspection for defects. This ensures compliance with international standards such as ASTM A276 for stainless steel and specific polymer grades.

➜ (Material Certification & QA)

Step 2: Precision Component Manufacturing

- CNC Machining: Complex metallic components, such as sensor housings, connectors, and mounting brackets, are fabricated using advanced 5-axis CNC (Computer Numerical Control) machining centers. This process ensures extremely tight tolerances (e.g., ±0.01mm) and complex geometries, critical for watertight seals and precise sensor alignment. The high precision reduces assembly errors and enhances product reliability.

- Injection Molding/Extrusion: Polymer parts, including cable jackets, protective caps, and some sensor bodies, are produced through high-precision injection molding or extrusion. This method allows for repeatable, intricate designs and ensures material integrity and resistance to chemicals and UV radiation.

- Surface Treatment: Metal parts undergo various surface treatments to enhance durability and corrosion resistance. This can include passivation for stainless steel (removing free iron and forming a protective oxide layer), anodizing for aluminum components, or specialized coatings for extreme environments. These treatments extend product lifespan significantly, especially in saline or chemically aggressive waters.

- Casting/Forging (for heavy-duty components): For certain robust structural components, such as valve bodies in integrated systems, precision casting (e.g., investment casting for intricate shapes) or forging (for maximum strength and impact resistance) processes are employed. These processes ensure superior mechanical properties and structural integrity, crucial for high-pressure or high-flow applications. All castings and forgings are subject to non-destructive testing (NDT) like ultrasonic testing or X-ray inspection to detect internal flaws.

➜ (In-process Quality Checks & Metrology)

Step 3: Sensor Integration & Calibration

This critical phase involves the delicate integration of optical, electrochemical, and acoustic sensing elements into their respective probes. This is performed in a cleanroom environment to prevent contamination. Each sensor unit undergoes individual calibration against NIST-traceable standards. For instance, pH sensors are calibrated using buffer solutions, and DO sensors are calibrated using air-saturated water and zero-oxygen solutions. Calibration data is stored and provided with each sensor, ensuring the accuracy of collected environmental data. This process ensures that the sensors deliver precise measurements within their specified ranges.

➜ (Automated Calibration & Traceability)

Step 4: Electronic Assembly & Firmware Integration

The sophisticated electronic circuits (PCBs) that power the sensors, process data, and enable communication are assembled in-house. This includes soldering, component placement, and board testing. Proprietary firmware, optimized for low power consumption and robust data handling, is then loaded onto the microcontrollers. Each electronic module undergoes functional testing to verify all communication protocols (e.g., RS485, SDI-12, Modbus) and data processing capabilities.

➜ (Functional Testing & EMI/EMC Compliance)

Step 5: Final Assembly & Sealing

Components are meticulously assembled into their final product form. This includes precise fitting of sensor probes, electronics, and power modules into their housings. Critical attention is paid to sealing mechanisms. For example, double O-ring seals, hydrophobic membranes, and specialized potting compounds are used to achieve IP67/IP68 ingress protection ratings, preventing water ingress and protecting sensitive electronics from the elements, ensuring long-term reliability in submersed or outdoor applications.

➜ (Pressure Testing & Leak Detection)

Step 6: Comprehensive Quality Control & Testing

Before dispatch, every Water Conservancy Product undergoes a stringent multi-stage testing regimen:

- Functionality Testing: Verifying all functions, including power on/off, sensor readings, data logging, and communication.

- Environmental Testing: Products are subjected to simulated harsh conditions, including temperature cycling, humidity tests, and vibration tests, to ensure performance across a wide range of operational environments.

- Submersion/Pressure Testing: For submersible instruments, units are pressure tested to simulate specified depths, verifying seal integrity and preventing water ingress.

- Long-Term Burn-in Testing: A batch of products undergoes extended operational testing to identify any potential early-life failures and confirm sustained performance.

- Final Calibration Check: A final verification of sensor calibration accuracy ensures that the product delivers precise environmental data out of the box.

- Compliance Verification: Adherence to internal QC standards (e.g., ISO 9001:2015) and external regulatory requirements (e.g., CE marking, FCC compliance for electronics) is confirmed.

➜ (Packaging & Dispatch)

This detailed manufacturing workflow underpins the superior quality, durability, and performance of our Water Conservancy Products, ensuring they provide reliable and accurate environmental data for years to come, even in the most demanding applications. Our adherence to standards like ISO 9001:2015 (Quality Management System) and ANSI/API guidelines for specific components ensures that every product reaching our customers is of the highest caliber.

Manufacturer Comparison: Why Choose Our Environmental Data Solutions

While the market offers various environmental data acquisition systems, Water Conservancy Products And Services stand out due to a unique combination of innovation, durability, and dedicated support. Below is a comparison highlighting our strengths against typical industry offerings:

This comparison underscores our commitment to delivering superior value through advanced technology, unparalleled durability, and comprehensive support, ensuring our clients receive the most reliable and actionable environmental data.

Customized Solutions for Diverse Environmental Data Needs

Recognizing that every water conservancy project presents unique challenges, our Water Conservancy Products And Services are designed for profound customization. We collaborate closely with clients to develop bespoke environmental data acquisition systems that precisely meet their operational requirements, budgetary constraints, and specific environmental conditions.

Our customization process typically involves:

- Needs Assessment: Detailed consultation to understand specific environmental data parameters required, deployment locations (e.g., remote rivers, industrial outfalls), communication infrastructure availability, and regulatory compliance needs. This includes defining the desired spatial resolution for mapping or the temporal frequency for real-time alerts.

- System Design & Engineering: Our team of hydrological engineers and data scientists drafts a tailored solution. This may involve selecting specific sensor types (e.g., specialized heavy metal sensors for mining sites, or high-range turbidity sensors for flood events), designing custom buoy or pole mounting systems, integrating specific power solutions (solar, wind, battery), and configuring communication modules (e.g., satellite for ultra-remote areas). We also design customized user interfaces for our data platform, ensuring intuitive access to critical environmental data.

- Prototyping & Testing: For complex projects, we can develop prototypes for client review and conduct rigorous field testing in simulated or actual deployment environments to validate performance and make necessary adjustments before full-scale production.

- Scalable Deployment & Integration: Whether it's a single monitoring point or a large-scale network across a river basin, our solutions are designed for seamless deployment and integration with existing SCADA (Supervisory Control and Data Acquisition) systems or other environmental management platforms.

- Post-Deployment Support & Training: We provide comprehensive training for client personnel on system operation, maintenance, and environmental data interpretation. Our ongoing technical support ensures smooth operation and maximum uptime, demonstrating our commitment to client success.

Our expertise extends to integrating various data sources, including satellite imagery for land cover change analysis, meteorological stations for weather impacts, and hydrological models to provide a holistic view of the water environment. This collaborative approach ensures that our clients receive a solution that is not just a product, but a strategic asset for their water resource management initiatives.

Application Cases: Real-World Impact of Environmental Data Solutions

Our Water Conservancy Products And Services have been successfully deployed in diverse and challenging environments globally, demonstrating their reliability and the profound impact of accurate environmental data. Below are illustrative examples of their application:

Case Study 1: Real-time River Quality Monitoring Network

Challenge: A major metropolitan area faced escalating concerns over industrial discharge and agricultural runoff impacting its primary drinking water source – a large river. Traditional manual sampling was infrequent and costly, failing to capture episodic pollution events or provide timely alerts for water pollution detection.

Solution: We deployed a network of 25 multi-parameter water quality monitoring stations along the river and its tributaries. Each station integrated sensors for pH, DO, turbidity, conductivity, chlorophyll-a, and specific ion probes for nitrates and phosphates. Data was transmitted in real-time via LoRaWAN and 4G to a central cloud-based platform. The system included automated alerts for parameter exceedances and predictive analytics to forecast water quality degradation.

Results: Within six months of deployment, the client reported a 70% reduction in detected pollutant concentrations due to faster identification and intervention. The continuous environmental data enabled pinpointing pollution sources, leading to targeted regulatory actions. Furthermore, operational costs for water treatment decreased by 15% due to optimized chemical dosing based on real-time influent quality. The system proved its reliability during a major rainfall event, providing crucial environmental data on turbidity spikes, allowing the water treatment plant to adjust filtration rates proactively, preventing supply disruptions. This project highlighted the system's ability to provide actionable data, transforming reactive management into proactive environmental stewardship.

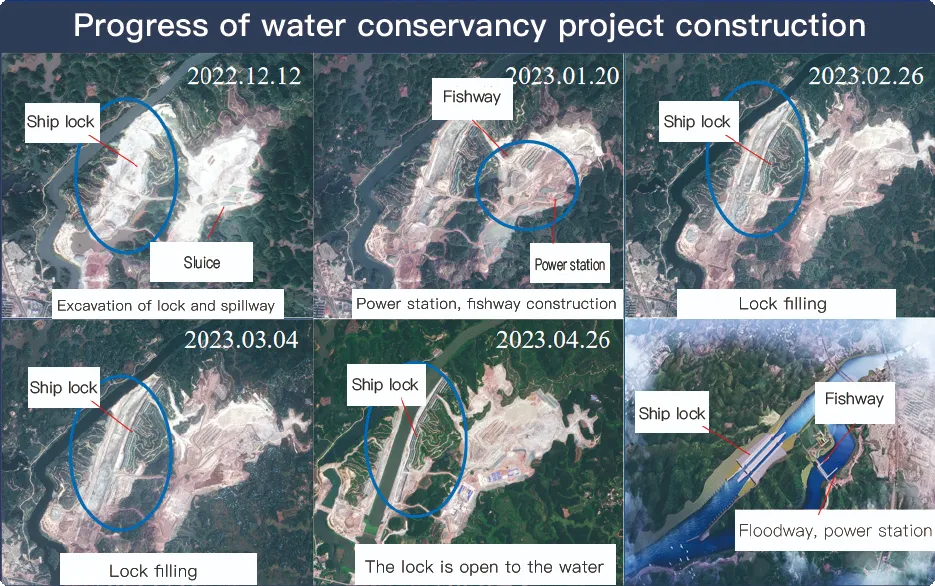

Case Study 2: Dam Safety and Reservoir Management

Challenge: A large hydroelectric dam required enhanced safety monitoring and optimized water release strategies, particularly during monsoon seasons, to prevent flooding downstream and ensure efficient power generation. Critical gaps existed in real-time water level, pressure, and structural integrity data.

Solution: Our solution involved installing high-precision water level sensors within the reservoir and downstream, coupled with pressure transducers on the dam structure. Additionally, our data acquisition platforms were integrated with existing meteorological stations for rainfall data. Furthermore, we implemented regular drone-based LiDAR surveys for highly accurate land cover change and structural deformation monitoring around the reservoir perimeter and dam body, providing spatial resolution down to 10 cm.

Results: The real-time environmental data enabled the dam operators to implement dynamic water release schedules, reducing flood risk by 20% and optimizing power generation by 10%. The LiDAR data, updated quarterly, identified subtle ground movements and erosion patterns on the dam's slopes, allowing for proactive maintenance before issues escalated. This comprehensive approach significantly enhanced dam safety and operational efficiency, serving as a model for critical infrastructure management. The system also facilitated compliance with dam safety regulations by providing a continuous audit trail of hydrological conditions and structural integrity data, showcasing its value beyond mere monitoring.

Case Study 3: Agricultural Irrigation Optimization

Challenge: A large-scale agricultural cooperative was struggling with inefficient water usage, leading to rising operational costs and concerns about groundwater depletion. They needed precise environmental data to move from time-based to demand-based irrigation.

Solution: We deployed a network of soil moisture sensors at various depths across their fields, integrated with weather stations providing local evapotranspiration data. This data acquisition system fed into a central dashboard, providing farmers with real-time recommendations for irrigation scheduling. We also incorporated satellite imagery for large-area land cover change and vegetation index analysis to monitor crop health across different parcels.

Results: The cooperative achieved a remarkable 30% reduction in water consumption for irrigation within the first season, leading to significant cost savings. Crop yields improved by an average of 8% due to optimized water delivery at critical growth stages. The integration of environmental data from various sources empowered precision agriculture, demonstrating how our solutions contribute to both economic viability and environmental sustainability. Farmers reported increased confidence in their watering decisions, reducing over-irrigation and nutrient leaching, which had a positive impact on local water quality.

Frequently Asked Questions (FAQ) about Environmental Data Products

- Q1: What is the typical lifespan of your Water Conservancy Products, especially for submerged sensors?

- A1: Our products are engineered for exceptional longevity. Components exposed to water, such as sensor housings and probes, are manufactured from marine-grade 316L stainless steel, titanium, or high-performance engineering plastics (PVDF, PEEK) that resist corrosion and bio-fouling. The typical design life for our critical sensing units is 5 to 10 years, and the main system enclosures and mounting hardware often exceed 15 years, minimizing total cost of ownership.

- Q2: What inspection standards do your products adhere to during manufacturing?

- A2: We adhere to stringent international quality management systems, notably ISO 9001:2015, throughout our entire manufacturing process. Specific product components and testing procedures also comply with relevant industry standards such as ANSI (American National Standards Institute) for dimensional tolerances and material specifications, ASTM (American Society for Testing and Materials) for material testing, and sometimes API (American Petroleum Institute) for robustness in critical applications, ensuring the highest level of reliability and safety.

- Q3: How often do the sensors require calibration, and what is the process?

- A3: The calibration frequency depends on the sensor type and the application environment. Our advanced optical and digital sensors typically require less frequent calibration, often every 6 to 12 months, compared to traditional electrochemical sensors. The calibration process is user-friendly, guided by our software, and can often be performed in the field using certified standard solutions. We also offer comprehensive calibration services and training.

- Q4: Can your systems be integrated with existing SCADA or telemetry platforms?

- A4: Absolutely. Our products are designed with open communication protocols (e.g., Modbus RTU/TCP, SDI-12, RS-485) and flexible data output formats (e.g., JSON, CSV), enabling seamless integration with most existing SCADA systems, telemetry units, and cloud-based data management platforms. Our technical team provides full support for integration and API documentation.

- Q5: What kind of customer support and warranty do you offer?

- A5: We offer a comprehensive support package including a standard 3-year warranty on all hardware components, with options for extended warranty plans. Our dedicated technical support team is available 24/7 for troubleshooting and remote assistance. We also provide on-site installation support, commissioning, and regular maintenance services, along with detailed product documentation and training sessions.

- Q6: How do your products contribute to energy saving and anti-corrosion?

- A6: Energy efficiency is a core design principle; our systems feature low-power components, intelligent power management, and optimized solar/battery solutions for prolonged autonomous operation, significantly reducing operational energy costs. For anti-corrosion, we exclusively use advanced materials like 316L stainless steel, titanium, and specialized polymers, along with superior surface treatments (e.g., passivation), ensuring exceptional durability and resistance to corrosive aquatic environments, thereby extending product lifespan and reducing replacement costs.

- Q7: What is the typical delivery cycle for a customized environmental data solution?

- A7: The delivery cycle for customized solutions varies based on complexity and component availability. For standard configurations, delivery typically ranges from 4 to 6 weeks after order confirmation. For highly customized or large-scale projects, the cycle may extend to 8-12 weeks, including design, prototyping, and extensive testing phases. We provide a detailed project timeline upon proposal approval, ensuring transparency and timely execution.

Ensuring Trustworthiness in Environmental Data Provision

Our commitment to trust in environmental data provision goes beyond technical specifications. We understand that actionable intelligence hinges on the veracity and integrity of the data. To this end, our processes and products are designed with the following principles:

- Transparent Data Provenance: Every data point collected by our systems includes metadata detailing its source, timestamp, sensor ID, and calibration status, ensuring full traceability and accountability.

- Robust Data Security: Data transmission utilizes industry-standard encryption protocols (e.g., TLS 1.2), and our cloud platform adheres to strict cybersecurity measures to prevent unauthorized access or manipulation of sensitive environmental data.

- Independent Verification & Validation: We encourage and support third-party auditing and validation of our data collection methodologies and platform performance, providing an objective assessment of data quality. Several of our projects have undergone independent reviews by environmental consultants.

- Continuous Improvement: Based on customer feedback and technological advancements, we regularly update our product firmware and software, providing over-the-air (OTA) updates to enhance functionality, accuracy, and security.

- Dedicated Technical Support: Our global support team, with expertise spanning over 15 years in water conservancy, is available to assist clients from planning and installation through to operational troubleshooting and data interpretation, building long-term partnerships based on mutual trust and shared objectives.

- Comprehensive Training and Documentation: We provide detailed user manuals, technical guides, and hands-on training sessions to empower clients with the knowledge and skills necessary to operate and maintain our systems effectively and interpret the environmental data confidently.

Our dedication to quality and reliability is evidenced by our ISO 9001:2015 certification, signifying a robust quality management system in design, development, production, installation, and servicing of our products. This ensures consistent quality and compliance with international standards, further cementing our trustworthiness in the sector of environmental data solutions.

Further Reading & Industry Insights

"The future of water management relies on integrated, real-time environmental data. Advances in sensor technology, coupled with sophisticated analytical platforms, are transforming our ability to monitor, predict, and respond to hydrological challenges, making sustainable water stewardship a tangible reality."

— Adapted from a discussion on 'Digital Water Management' at the World Water Forum.

- Leveraging satellite data for water resource management: A review - Nature Sustainability

- Special Issue: Recent Advances in Water Quality Monitoring - Sensors (MDPI)

- UN-Water: Towards a sustainable management of water resources - United Nations